Custom Engineering

Custom Engineering Of Micro Motion Systems

Creating next-generation products? We can help you build them smaller … make them smarter… and do it faster!

We work with you to develop custom motion modules and systems that meet your exact requirements, using our configurable M3 design platform or developing a full-custom micro motion module.

Custom project examples

Here are just a few examples of our custom motion system projects.

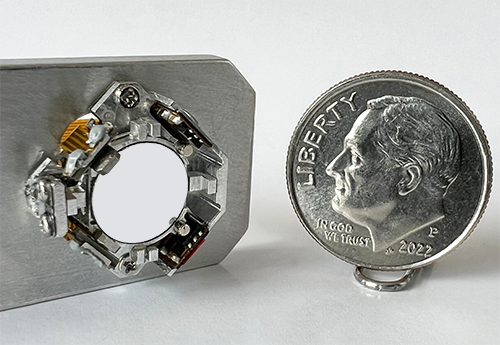

Two-axis tilting mirror module - M3-TMM-U2-4.5-6 (preliminary)

Patented UTAF piezoelectric ultrasonic motors in a planar configuration move a single mirror in two independent orthogonal axes. Motor drivers, position sensors, and communication are built in to the module, making it an all-in-one solution for controlling laser beams in multiple axes.

- 14 X 14 X 7 mm size

- +/- 8 degrees of tilt in both axes

- 0.01 degree resolution and 0.02 degree repeatability

- 15 millisecond step and settle for 0.5 degree step

- 3.3 VDC input with off-power hold

- Built-in controller accepts digital commands via SPI or I2C interface

This module is being commercialized as the M3-TMM-U2-4.5-6 Two-Axis Tilting Mirror Module. Developer’s Kits are available for pre-order.

Download the preliminary data sheet (PDF)

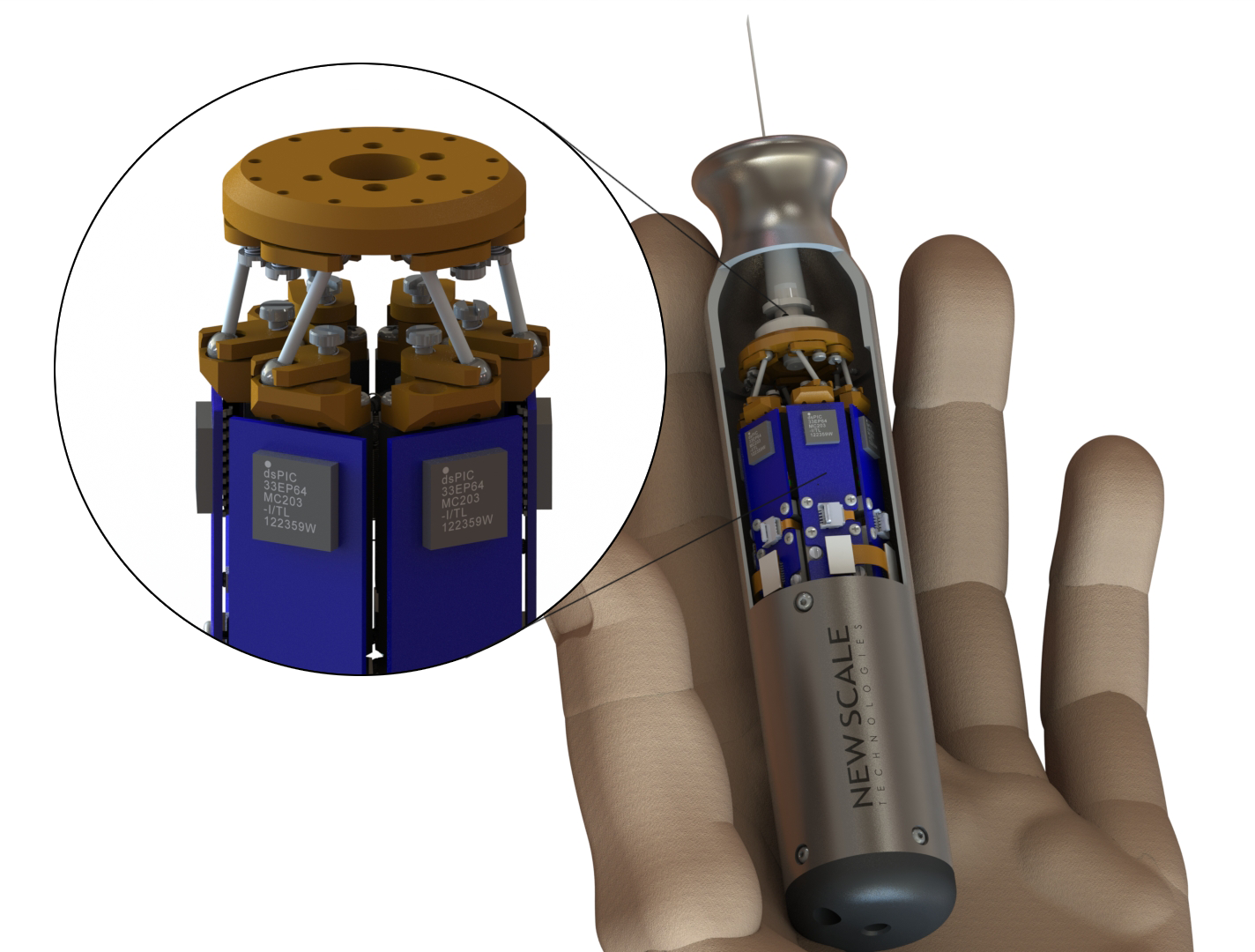

Hexapod system

We collaborated with Carnegie Mellon University to develop a hexapod system using six piezoelectric SQUIGGLE micro motors integrated with miniature bearing assemblies, motor mounts, flexures and spring preloads. Drive electronics, integrated into the miniature handheld micromanipulator, dynamically adjust drive parameters to optimize performance of each motor under varying conditions including changing temperature and side loads.

Development continues under a Phase 1 SBIR grant awarded by the National Eye Institute of the National Institutes of Health (NIH), preparing the way for a clinically-compatible product ready for commercialization. The fundamental hexapod design is available as a launch point for further development and customization in other applications. Download preliminary information (PDF)

Multi-axis positioning systems

In this example, two-axis linear positioners fit in an 80 mm space for eight independent axes of motion with closed-loop position resolution of 0.5 μm.

Focus for a gigapixel camera

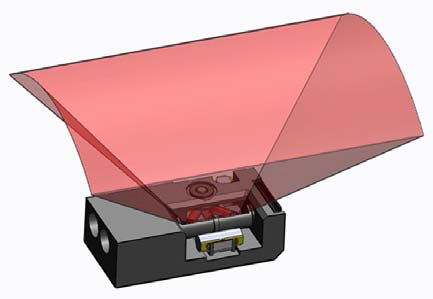

Custom beam steering modules

accommodate higher-power lasers with larger beam diameters. They are the smallest and easiest-to-integrate beam steering solutions available. This bulletin describes several different custom M3 modules developed for specific beam steering requirements. We also offer standard M3-RS rotary stages for beam steering using a familiar galvano-scanner

style form factor.

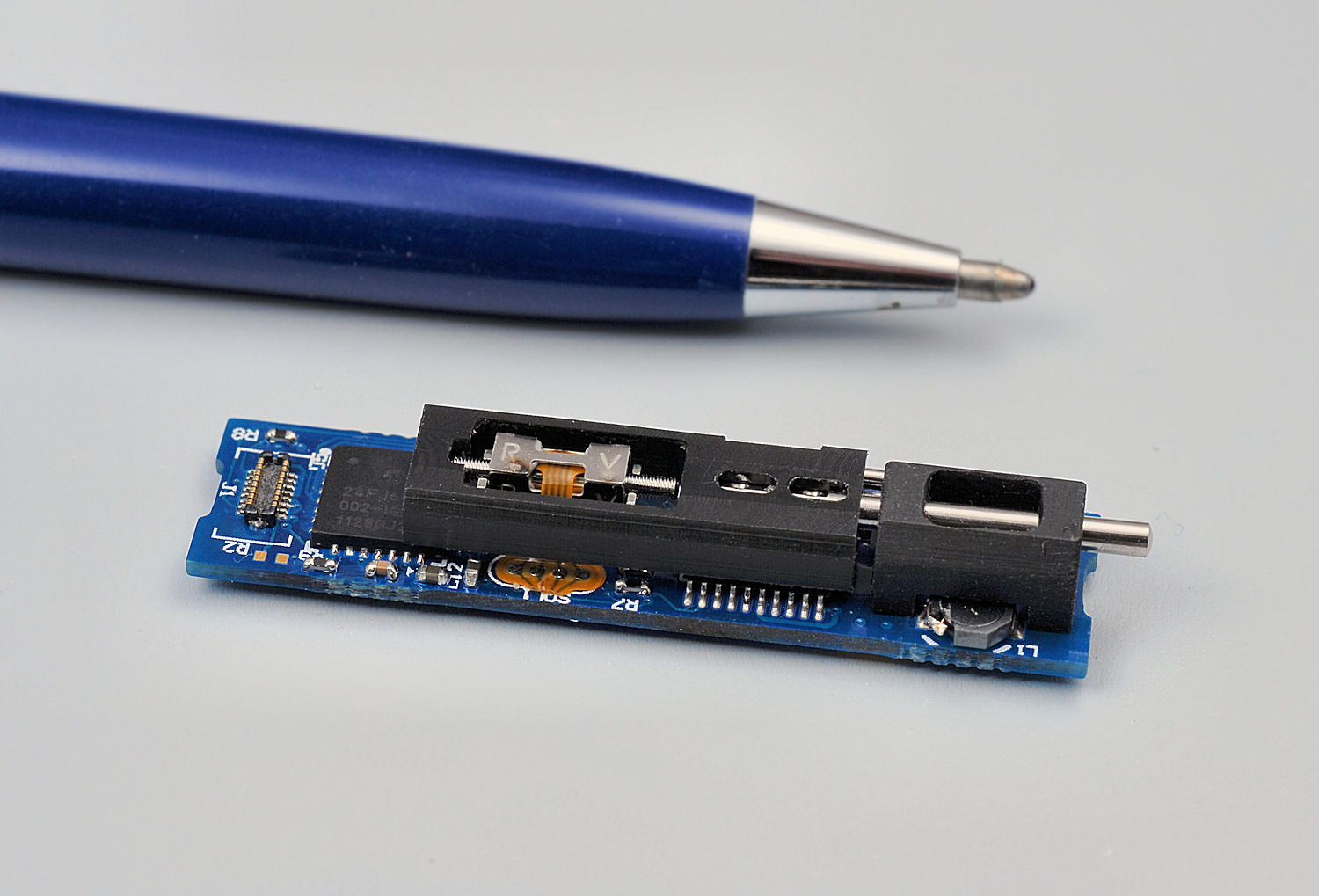

High-torque two-stage rotary motor system

This rotary micro motor can be optimized for other design parameters including smaller size, higher torque or higher speeds. It is scalable to less than 2 mm diameter. Input to the controller is simple, high-level commands over standard serial interface.

These slender rotary micro motors were originally developed for NASA Jet Propulsion Laboratory’s “Cobra” fiber positioner to be commissioned on the Subaru Telescope on Mauna Kea, Hawaii. In this application, two rotary motors are mounted in a theta-phi configuration.

Electrically integrated drive electronics are physically separated from the motor by a short flex cable, to meet the form factor requirements.

This material is based upon work supported by the National Astronomical Observatory of Japan under Award No. 037151, the University of Japan, the John Robinson Endowment and the California Institute of Technology.

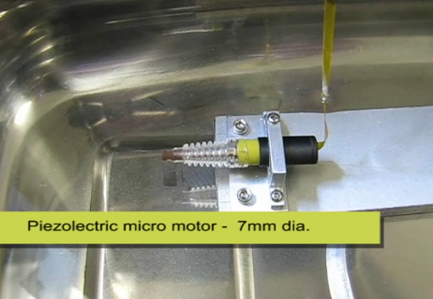

Moisture-resistant motor

The motor measures 7 mm diameter, has a force of 2 Newtons and moves with a position resolution of 0.5 micrometers. It has an external driver.

Custom high-force motors

A SQUIGGLE micro motor is customized with a water-resistant housing for operation in high-moisture environments or implantable medical devices. The housing also enables operation in clean room settings.

The motor measures 7 mm diameter, has a force of 2 Newtons and moves with a position resolution of 0.5 micrometers. It has an external driver.

Rotary micro-drive eliminates jitter

The piezoelectric motor generates no magnetic fields when moving, eliminating a source of potential interference with sensitive instruments in the OEM system.

It is also smaller than a servo drive, offers higher position resolution, and exhibits excellent velocity, acceleration and repeatability characteristics.

Get started with your custom motion module

We work with our OEM partners to develop custom motion modules and systems that meet your exact requirements, using our configurable M3 design platform or developing a full-custom motion module for a specific application.