UTAF micro motor technology

Inside the M3 Module

Ultra-Thin Actuator Family (UTAF) piezoelectric micro motor

UTAF motors are available only within our M3 Smart Modules and custom motion systems.

New Scale’s patented UTAF micro motor integrates all ultrasonic motor functions into a single piezoelectric ceramic beam measuring only 4.5 X 0.82 X 0.7 mm. It can produce either linear or rotary motion. This technology is used in New Scale motion modules and is available for licensing in high-volume applications.

Features

- Precise: 0.5 μm resolution

- Fast: > 10 mm/sec (linear) or > 300 deg/sec (rotary)

- Tiny: 0.7 x 0.8 x 4.5 mm

- Quiet and smooth

- Strong: 0.02 N stall force (linear) or high torque depending on diameter (rotary)

- Low power: 2.8 V, less than 150 mW moving, 0 mW to hold position

Operating Principle

The UTAF motor uses an innovative co-fired multi-layer ceramic process to create a single beam composed of many thin layers of piezoelectric ceramic material. Sub-segments of the monolithic beam are energized independently, causing the beam to vibrate simultaneously in two orthogonal directions.

The vibrations are used to move an object – such as a lens – placed in direct friction contact with the beam. UTAF motors can be used to produce either linear or rotary motion. Frequency, phase and amplitude of the ultrasonic vibrations are controlled by a two-phase drive circuit. Patented Smart Step control algorithms optimize speed and accuracy.

Because the layers are very thin, they respond to signals of 3 volts or less. This allows the UTAF motor to operate directly from a portable device’s battery.

Linear UTAF motion

Rotary UTAF motion

M3 smart modules, microstages and focus modules

New Scale combines UTAF technology with numerous other innovations to deliver complete “smart” actuator modules and microstages. These innovations include advanced drive electronics and motor control algorithms, high-efficiency pin-bushing guides and precision bearings, and innovative position sensor technology. All drive electronics are in the module – you just provide 3.3V and simple, high-level motion commands over a standard serial interface.

Rotary applications include a Risley device designed for an endoscopic laser scalpel, and a very compact micro-mirror positioning system. Linear applications include an Ultra-Thin Auto Focus module for micro camera systems.

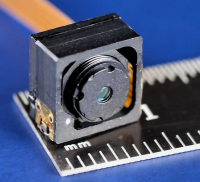

Patented ultra-thin UTAF motor with drive IC.

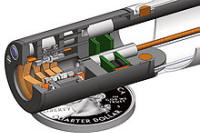

Ultrasonic vibrations of the UTAF motor cause a frictionally-coupled object to rotate.

Rotary mirror module with UTAF actuator and integrated drive electronics enables mirror rotation of +/- 20°.

Linear lens focus module with UTAF actuator and integrated drive electronics enables faster focus and continuous autofocus in thin cameras.

UTAF actuators rotate optics in a Risley device, an extremely compact and precise beam steering module with integrated drive electronics.