New Scale Technologies’ piezoelectric lens motion system delivers best-in-class performance for high-resolution miniature cameras in biometric, medical, machine vision and other applications

Victor, NY — July 25, 2011 — New Scale Technologies has upgraded the lifetime specification and provided new repeatability data for its miniature M3-F focus module, which replaces fixed lens holders in compact board cameras for biometric detection, medical diagnostics, machine vision and other applications.

Based on continuous design improvements and testing, the new lifetime specification is >2 million cycles mean time before failure in a fixed orientation or >500,000 cycles in random orientation. The position repeatability is +/- 5 microns uni-directional and +/- 20 microns bi-directional, demonstrating best-in-class performance for high-resolution imaging applications. Complete specifications and updated data sheet can be found here.

“Image quality is directly proportional to lens position repeatability with autofocus algorithms such as image resolution hill climbing,” said David Simpson, vice president of marketing and sales for New Scale. “Our testing confirms that the M3-F module out-performs competing miniature focus solutions in resolution, and is highly competitive in terms of lifetime. With the added benefit of lower external processing requirements and lower overall system cost, the M3-F module is the clear winner for compact, high-resolution camera applications.”

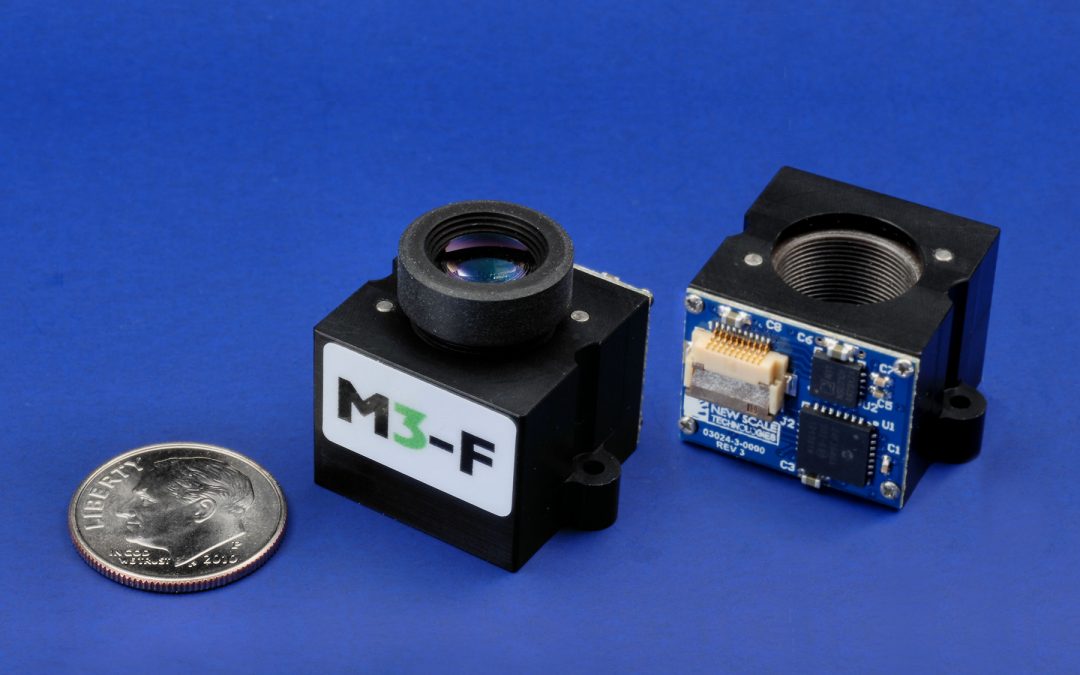

With a total footprint of 20 x 22 x 16 mm and no external control board, the M3-F easily replaces fixed lens holders over CCD or CMOS imager sensors without adding to the camera size. The M3-F accepts high-quality glass or polymer lenses, which have greater transmission and clarity than non-traditional composite lenses of liquid or liquid crystal. The embedded closed-loop drive delivers high repeatability, low temperature dependence and no hysteresis.

The M3-F module is based on New Scale’s M3 micro-mechatronic design platform and incorporates a piezoelectric SQUIGGLE micro motor, drive ASIC, magnetic NSE-5310 position sensor and a microprocessor in a robust polymer housing. It accepts standard threaded lens assemblies from M8 to M12 and is compatible with image sensors up to 17×17 mm, including the 1/2″ and 1/1.8″ formats.

About New Scale Technologies

New Scale Technologies develops small, precise and smart motion systems for critical adjustments of optics in imaging devices and many other micro positioning applications. Our simple and elegant solutions deliver best-in-class performance in consumer imaging, biometric authentication, surveillance, medical devices, scientific instruments, haptic systems and many other markets. We design and manufacture custom products and license our technology to manufacturers worldwide. Our customers benefit from complete motion solutions that are tailored to their unique requirements and easily integrated into their next-generation instruments.

SQUIGGLE is a registered trademark, and New Scale Pathway and UTAF are trademarks of New Scale Technologies, Inc.

Please note: Press releases are current as published, but are not updated after posting. Refer to our main pages for current information including specifications.