Apr 2, 2024 | Application Notes

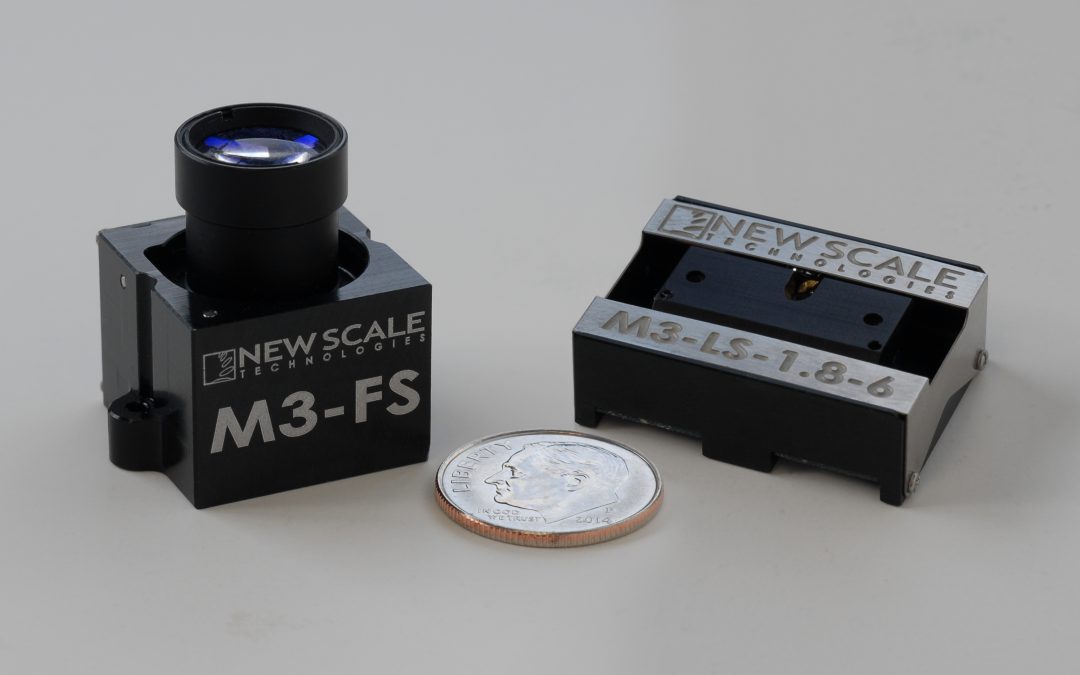

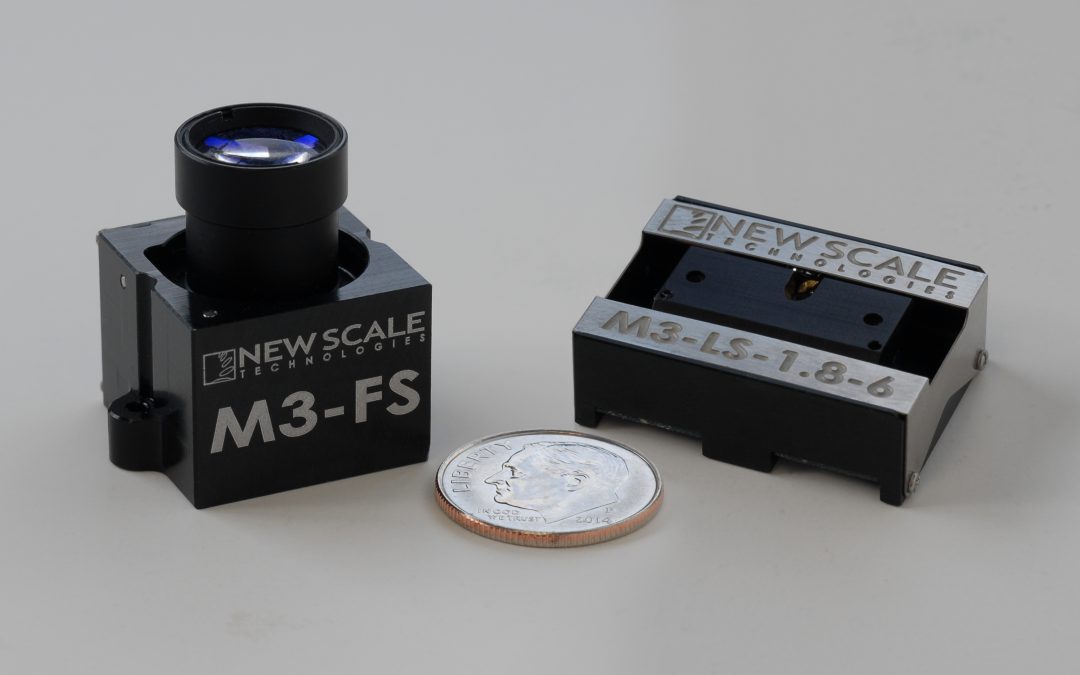

Prior to purchasing the M3-FS or M3-F Focus Module Developer’s Kit, you should verify compatibility of configuration to your lens and imager format. This design note outlines how to validate system compatibility.

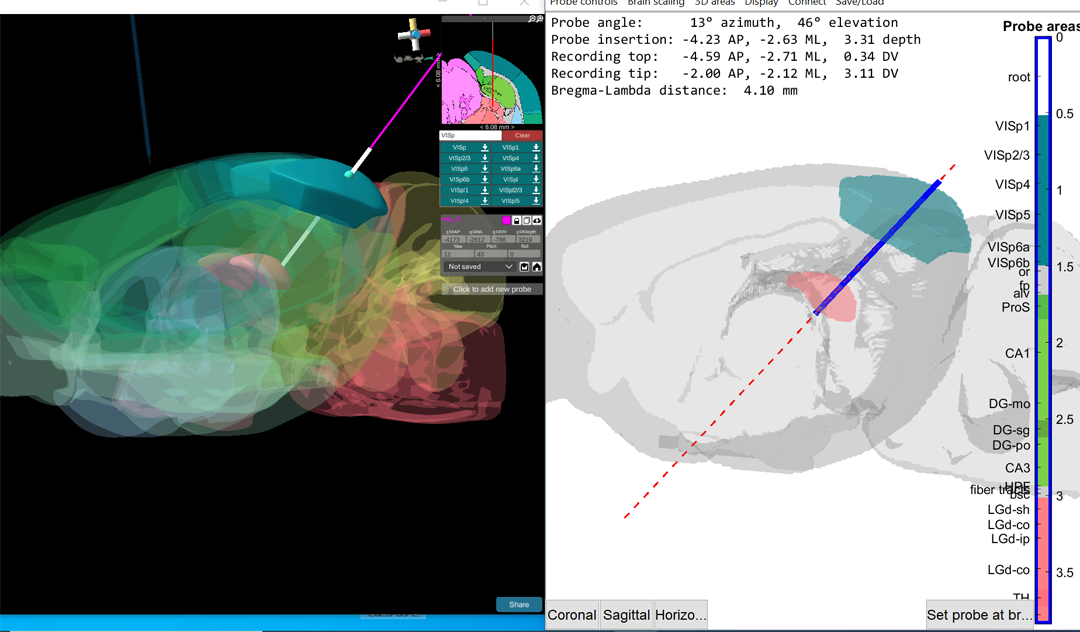

Oct 31, 2023 | Blogs, Neuroscience Blog

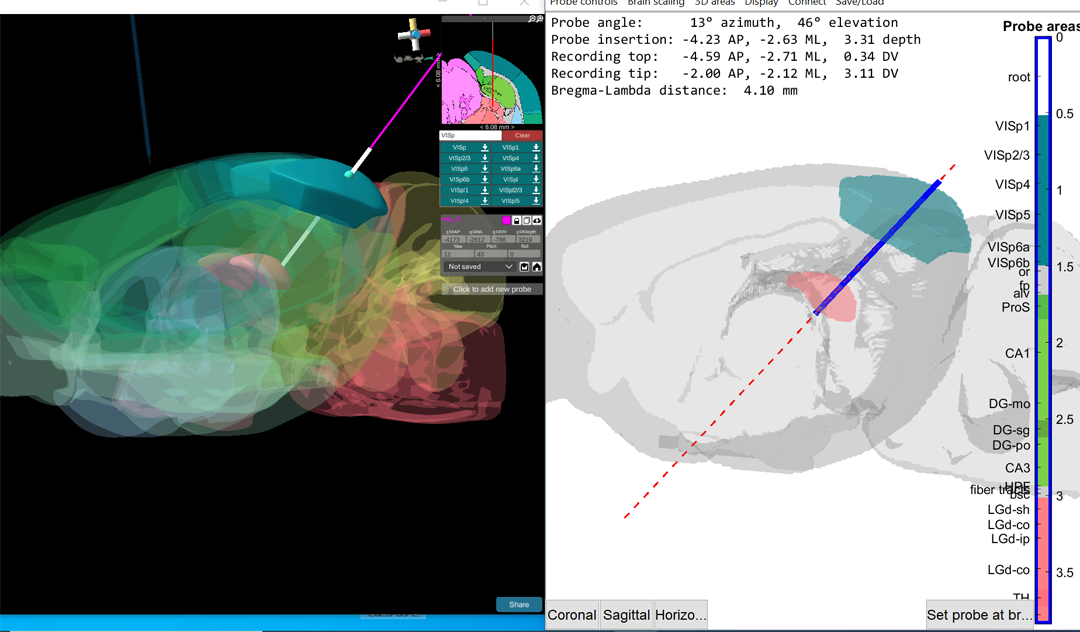

Two open-source trajectory planning tools – Pinpoint (left) and Neuropixels Trajectory Explorer (right) – interface with New Scale’s Pathfinder software for neural probe positioning. The developers of the Neuropixels Trajectory Explorer and the...

Feb 19, 2021 | Videos

Precision focus for the smallest OEM cameras in handheld, portable and mobile instruments. This is the developer’s kit for our new, high-precision M3-FS focus module for OEM system designers. It’s a miniature focus system that you can use in your new handheld,...

May 30, 2017 | News, Top News

Latest addition to “all-in-one” microstage stage family moves >100 gram loads with 500 nm resolution over 15 mm travel

Apr 24, 2017 | Videos

Manufacturing piezo motion systems with embedded controllers. New Scale Technologies develops and manufactures precision micro-motion modules, micro stages and piezoelectric motors at our advanced manufacturing center near Rochester, NY. Here is a look at the...

Apr 3, 2017 | Application Notes

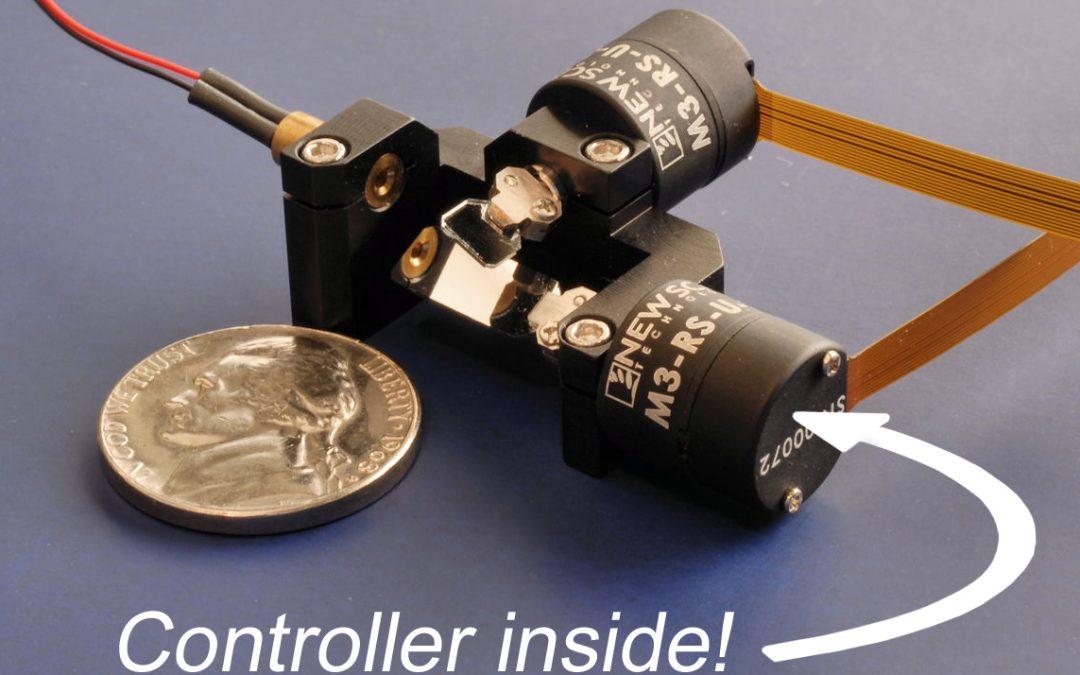

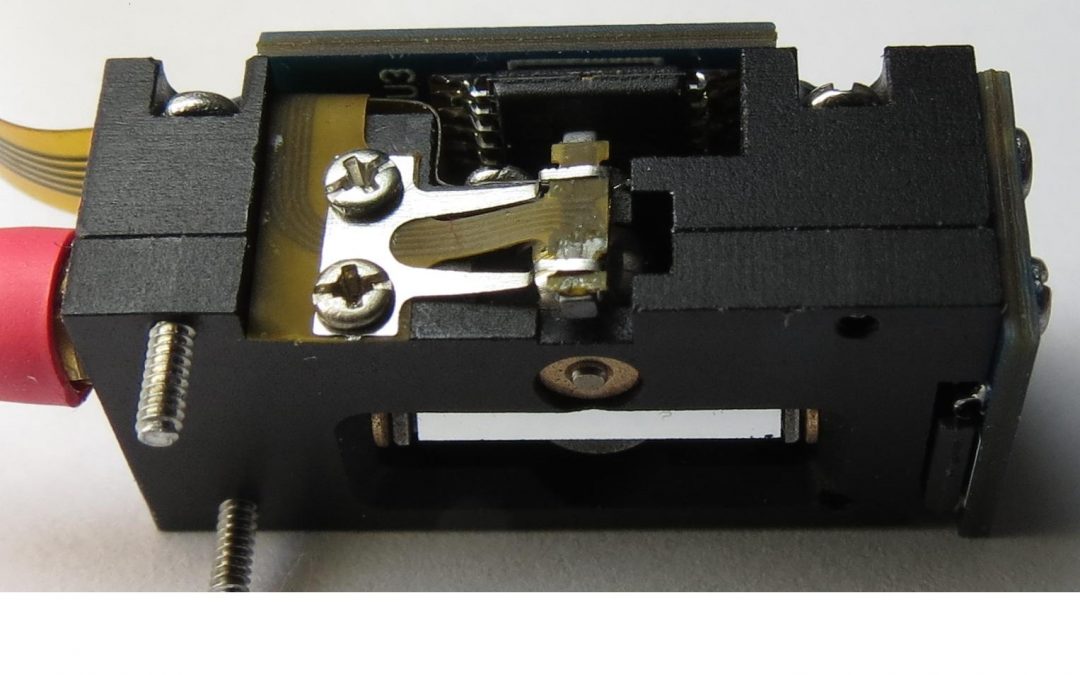

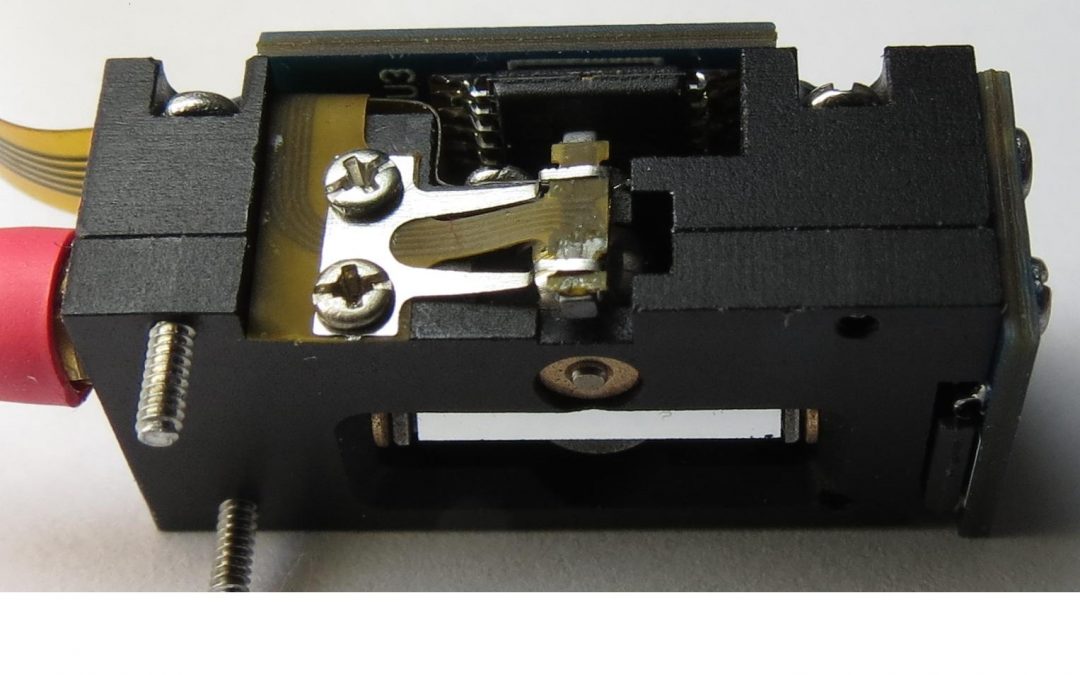

M3 micro-mechatronics modules are “all in-one” smart modules, with the controller and position sensor built in to the miniature module. This embedded closed-loop control gives you the smallest size, fastest and simplest integration into your system, and lowest total cost. When the application requires, M3 Smart Modules can also move using open-loop commands from the SPI, I2C or UART interface. This is particularly useful in applications that have an external sensor with better resolution than the internal sensor, or where very fast “step and settle” performance is required.

Feb 16, 2017 | News

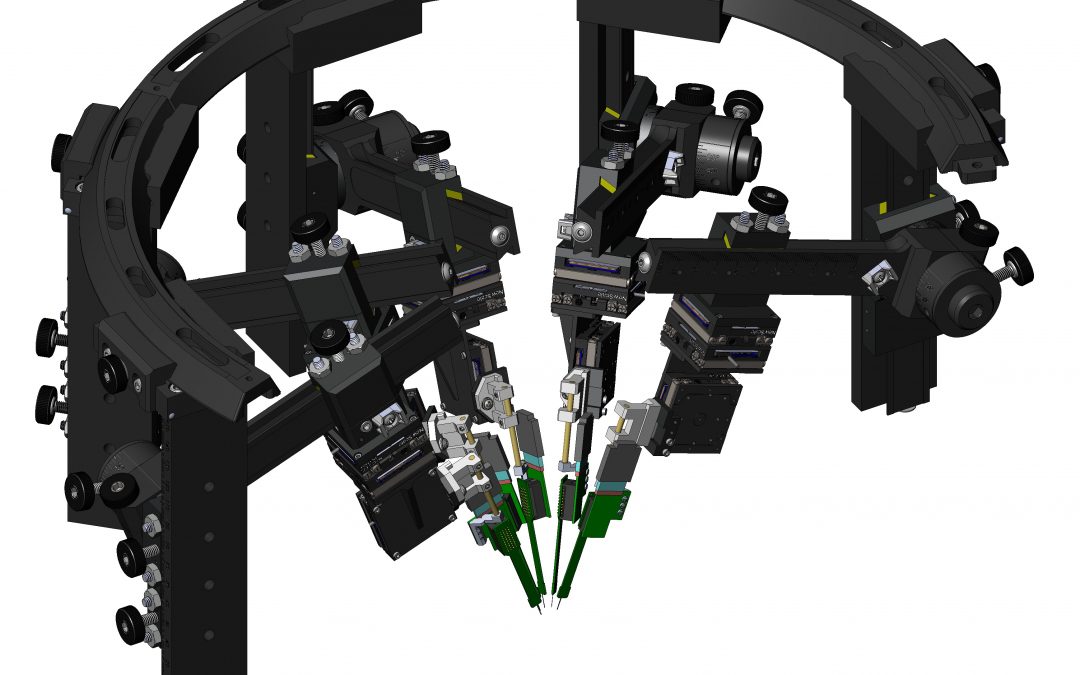

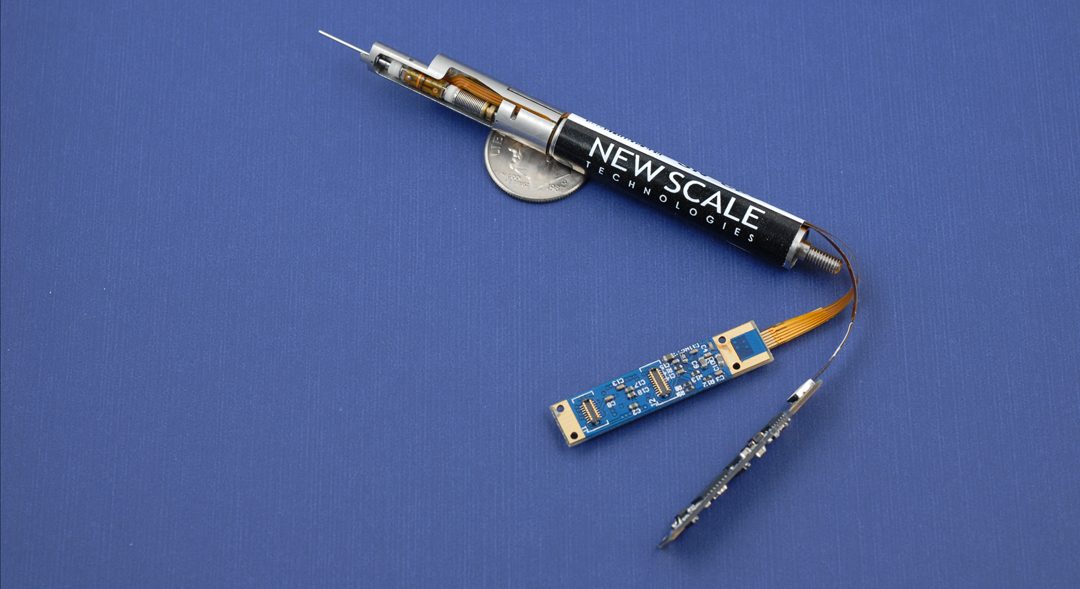

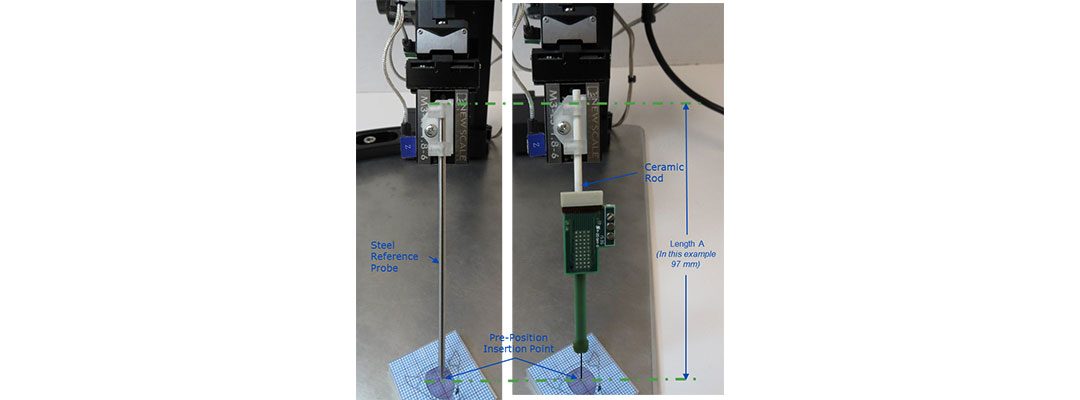

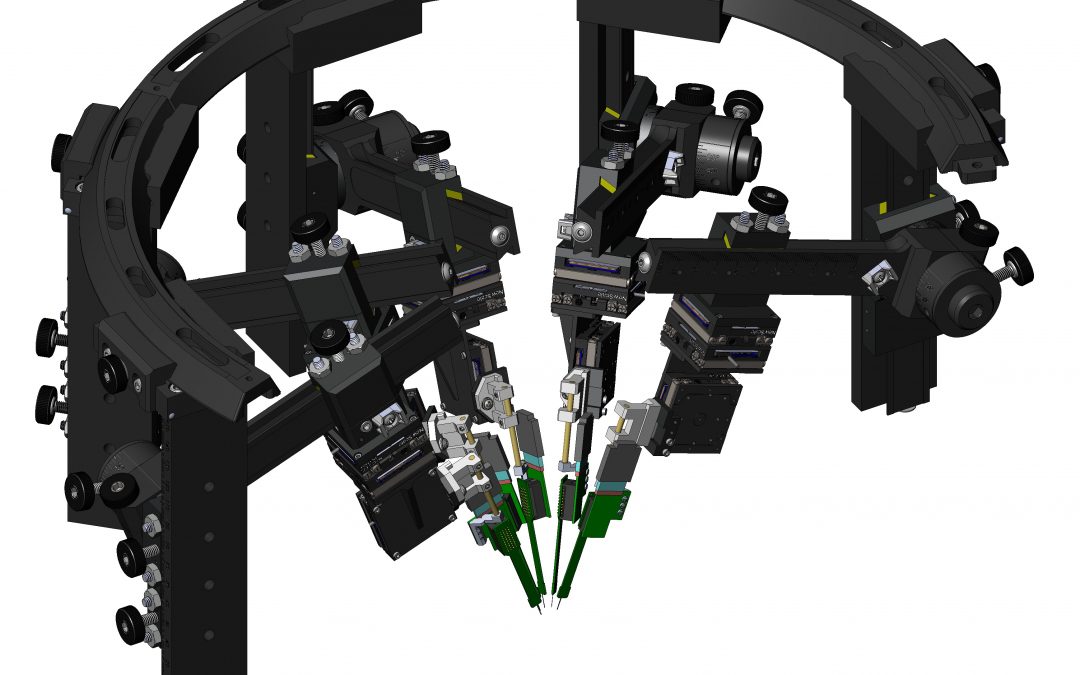

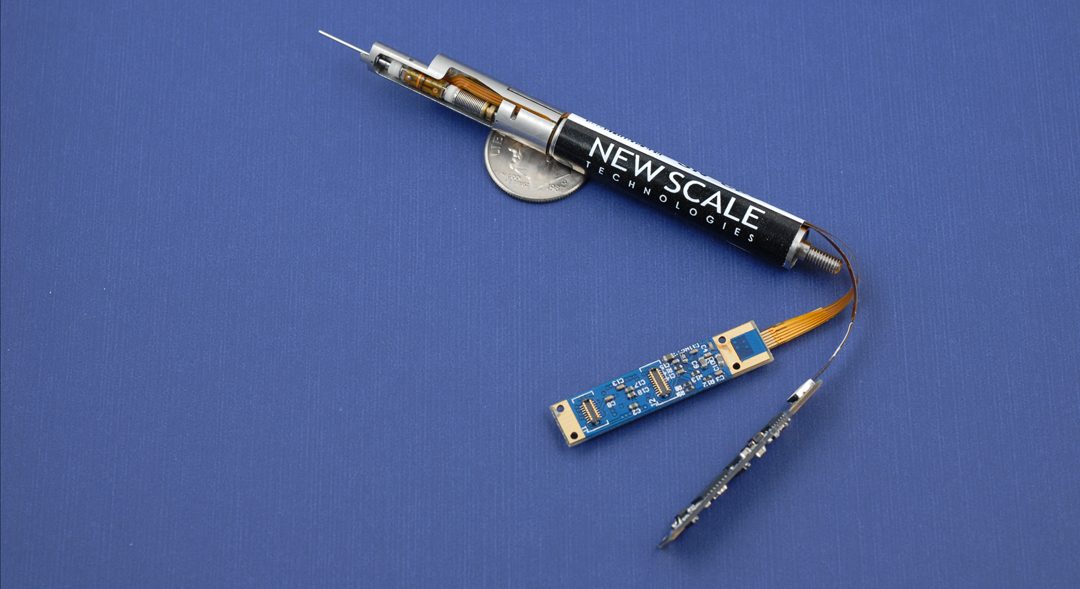

The MPM System, the first multi-probe micro-manipulator optimized for use with new silicon neural probes, enables high-yield acute in-vivo brain recording and optogenetics

Dec 20, 2016 | News, Top News

Rotary piezoelectric smart stages with embedded controllers make the system smaller, easier to use than galvo systems

Nov 29, 2016 | News, Top News

Developed with leading researchers, the MPM System is the first micromanipulator optimized for silicon probe insertion and independent, automated positioning of five or more probes simultaneously.

Nov 10, 2016 | Micro Motion Blog, Neuroscience Blog

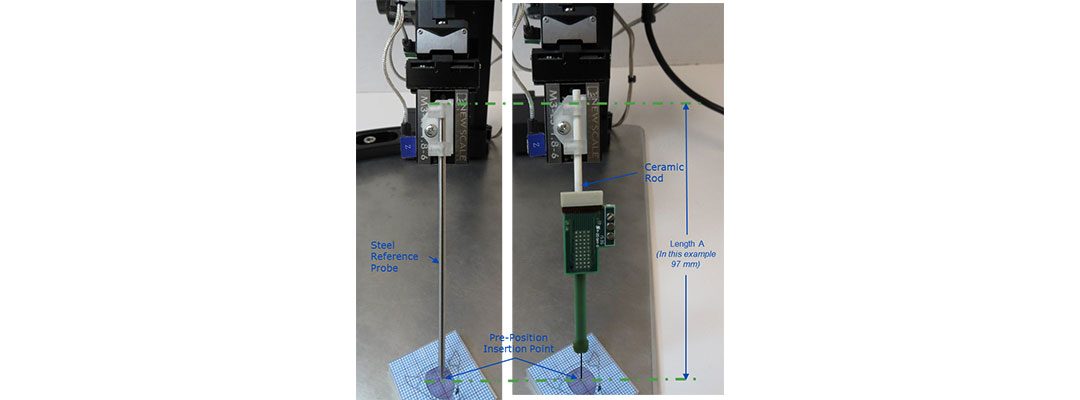

Case Study: A neuroscience researcher successfully used M3-LS Linear Smart Stage assemblies for positioning of probes during in-vivo recording. New Scale engineers then collaborated on an integrated multi-probe positioning assembly to meet the needs of this market.

Oct 11, 2016 | Micro Motion Blog

Case study: Piezo focus system enables portable cytometers, expands access to healthcare in resource-limited settings. A customer wanted to create a backpack-portable blood analyzer for use in resource-limited settings that do not have access to institutional laboratory instruments and services. New Scale’s miniature precision focus system helped to make it possible.

Jul 14, 2016 | News

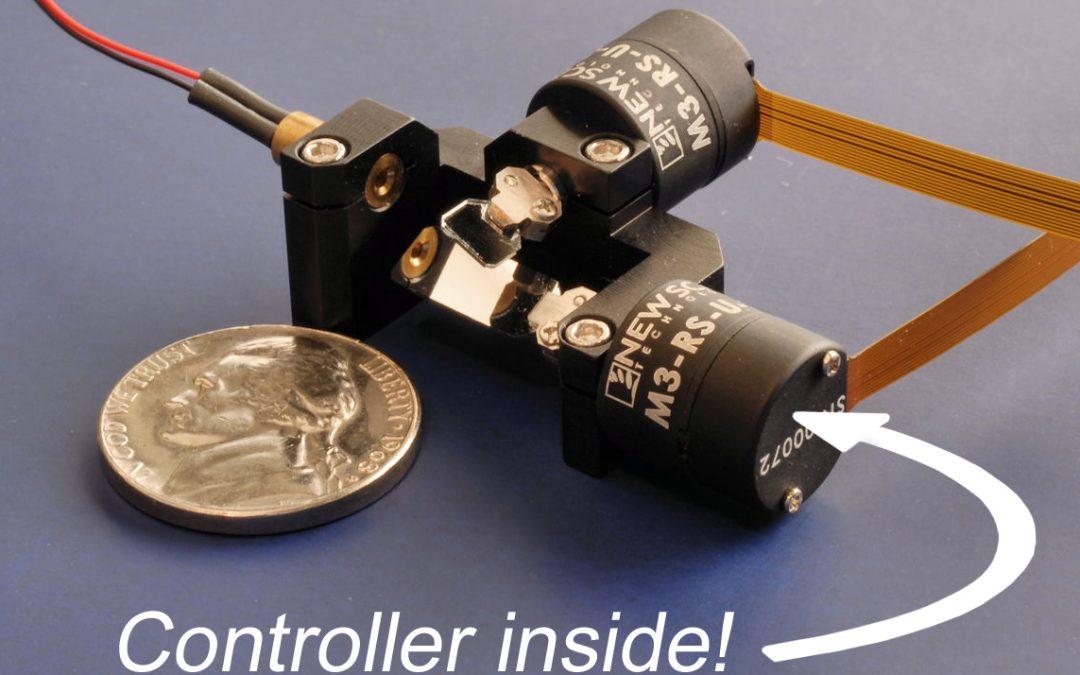

Patents cover a new rotary piezoelectric motor that achieves very high rotational speed with significant torque in a very small diameter, and a compact wide-angle optical beam steering assembly that has been commercialized in the M3-RS-U Rotary Smart Stages and beam steering developer’s kits.

Jun 22, 2016 | News

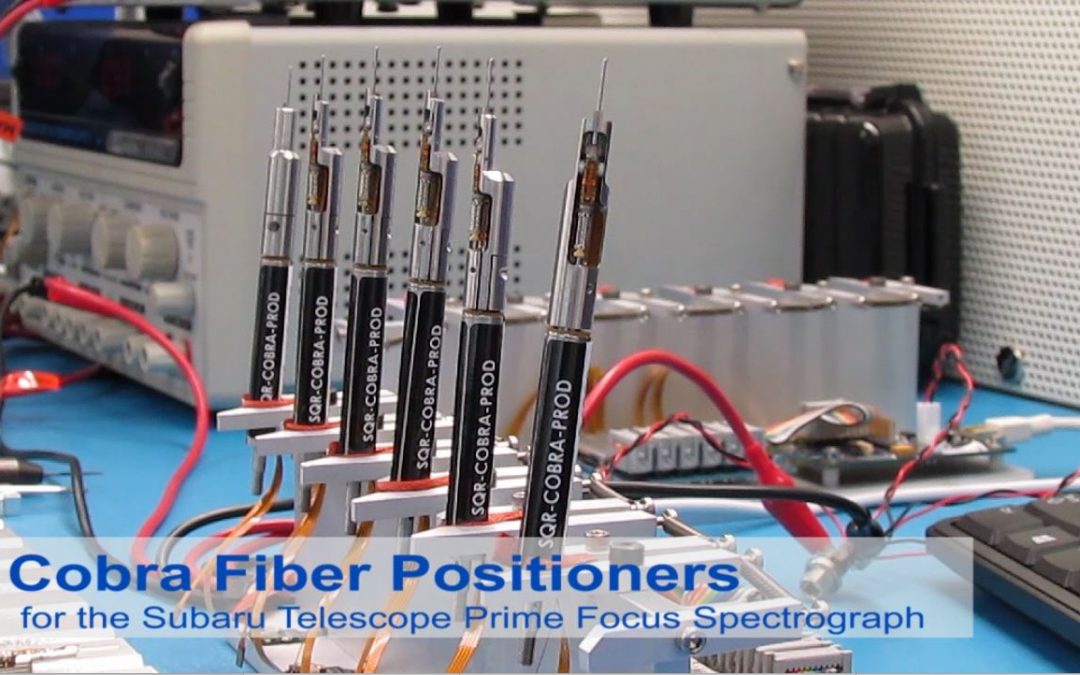

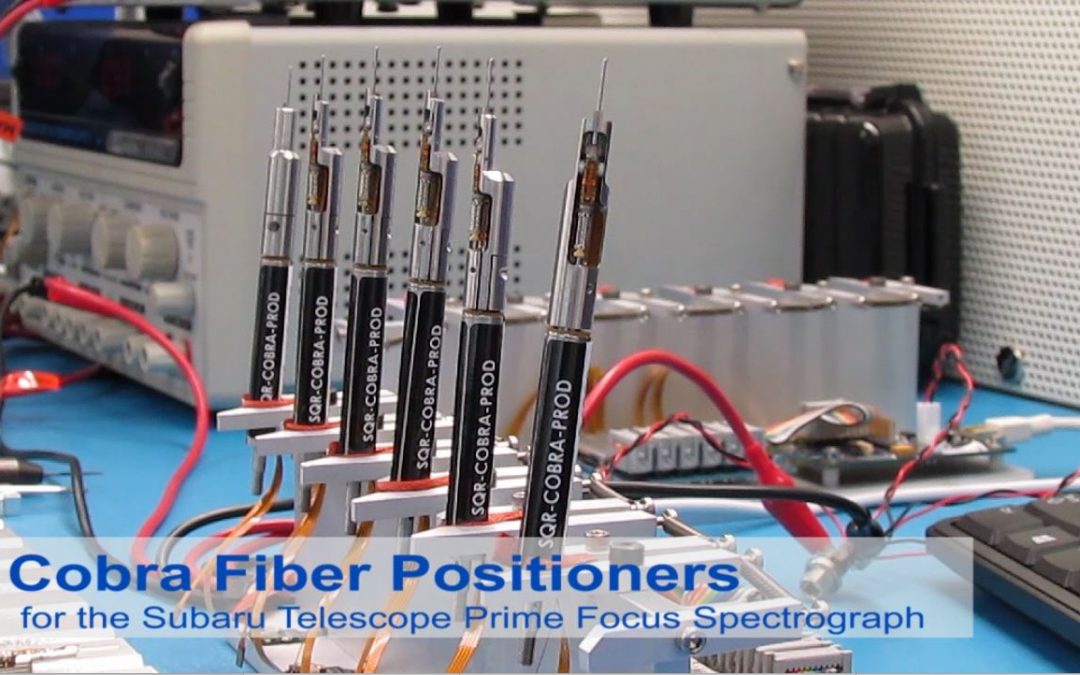

New Scale Technologies has achieved full-scale production of 200 Cobra positioners per month at its advanced manufacturing center near Rochester, NY. Mature processes for production and testing enable New Scale to support fiber spectrometer programs with the volume,...

Jun 13, 2016 | Videos

New Scale deploys its manufacturing equipment, process capability and micro-assembly experience to meet the volume, consistency and quality needs of its customers. In May 2016 New Scale achieved full production capacity — 200 per month — of Cobra fiber...

Jun 9, 2016 | News

Miniature M3-FS Focus Module and M3-LS Linear Smart Stage with built-in controllers have new, dramatically improved lifetime specification of >10 million moves.

Jun 8, 2016 | Application Notes

New Scale worked with NASA JPL/Caltech to design and manufacture a fiber optic positioning system using rotary piezoelectric SQUIGGLE micro motors for the Prime Focus Spectrograph (PFS). The PFS is a fiber fed multi-object spectrometer for the Subaru Telescope that will conduct a variety of targeted surveys for studies of dark energy, galaxy evolution, and galactic archaeology. The key to the instrument is a high density array of fiber positioners placed at the prime focus of the Subaru Telescope. The system, nicknamed the “Cobra” fiber positioner, will be capable of rapidly reconfiguring the array of 2,394 optical fibers to the image positions of astronomical targets in the focal plane with high accuracy.

Apr 11, 2016 | Medical Applications, News

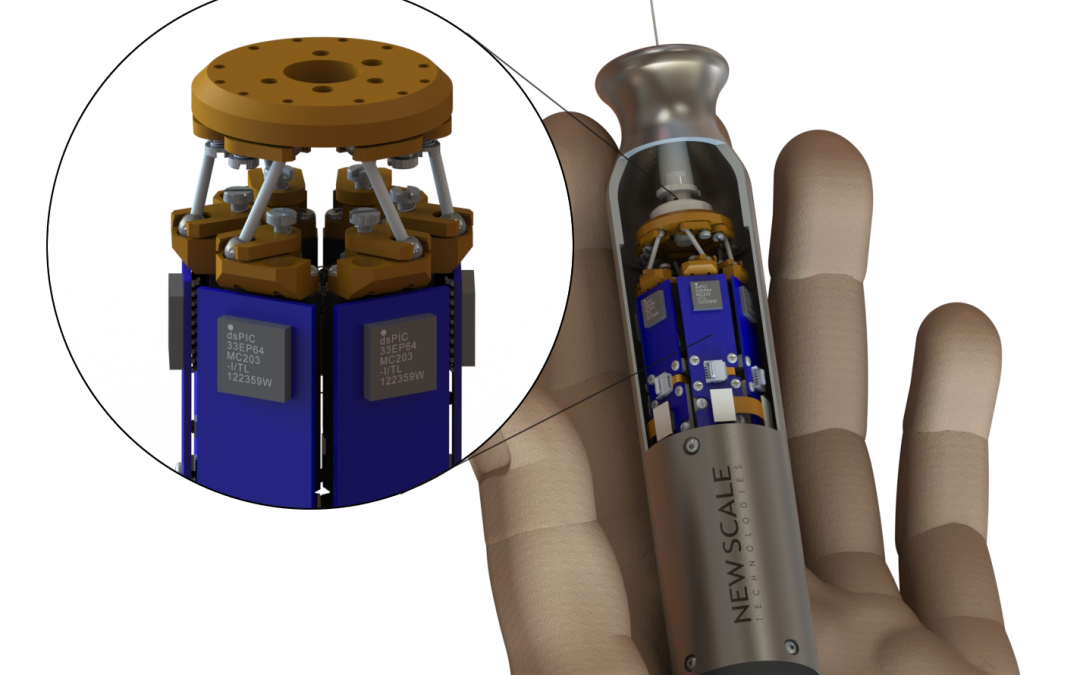

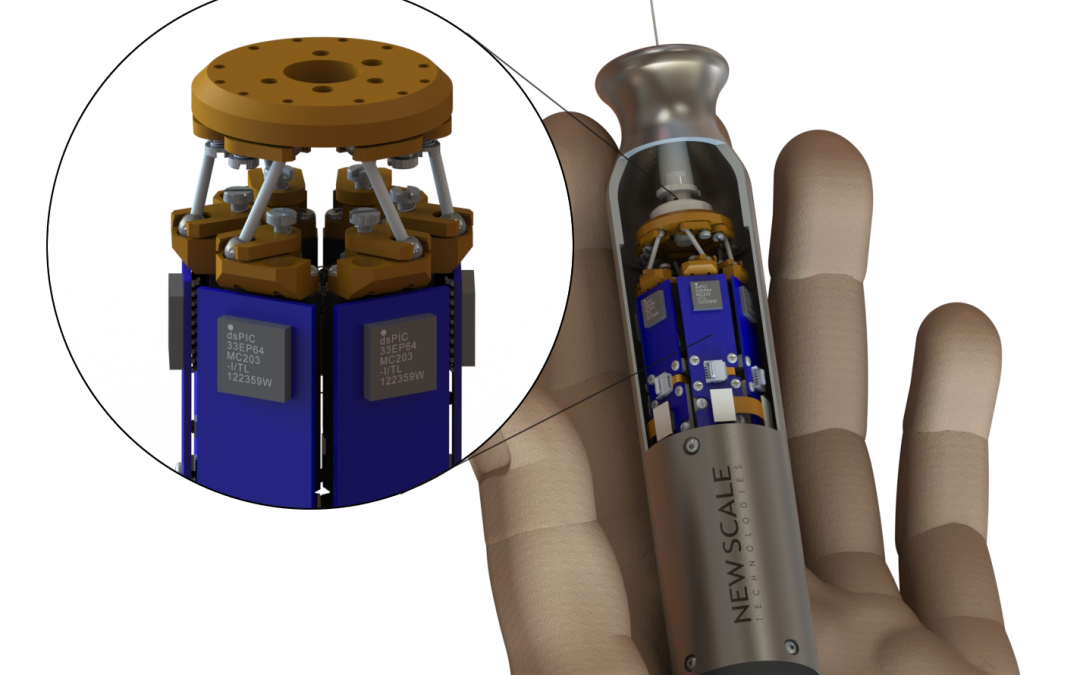

New Scale Technologies has been awarded an SBIR grant from NIH to develop a miniature commercial hexapod, a tiny six-degree-of-freedom micromanipulator. Tiny micro-positioner has applications in retinal microsurgery, robotic end-of-arm tooling, MEMS and photonics...

Mar 8, 2016 | News

The M3-RS-U two-axis beam steering system with built-in controller was the most popular demo in our booth at Photonics West and Bios 2016. Here are a few of the questions that we answered most often at the show.

Mar 3, 2016 | Application Notes

M3 micro-mechatronics modules are “all in-one” smart modules, with the controller and position sensor built in to the miniature module. This embedded closed-loop control gives you the smallest size, fastest and simplest integration into your system, and lowest total cost.

When the application requires, M3 Smart Modules can also move using open-loop commands from the SPI, I2C or UART interface. This is particularly useful in applications that have an external sensor with better resolution than the internal sensor, or where very fast “step and settle” performance is required.

Dec 11, 2015 | Micro Motion Blog

Article: New Scale’s micro beam steering solutions for handheld devices are among Laser Focus World’s Top 20 Technology Picks for 2015.