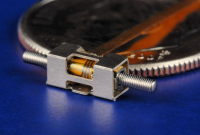

SQUIGGLE micro motor technology

Inside the M3 Module

The SQUIGGLE motor: The world’s smallest linear motor drives microstages, focus modules and more

This patented ultrasonic motor creates high force (or torque) and high speed with only a few parts – compare to complex electromagnetic gearhead motors with hundreds of parts. SQUIGGLE micro motors allow product designers to add motion features into products where they could not have been imagined before.

This simple, robust piezo motor is scalable to much smaller sizes than electromagnetic motors, without significant loss of power efficiency, and operates on 3.3 V. This makes it ideal for hand-held and portable products.

Features

- Precise: nanometer resolution

- Fast: variable speed to 10 mm/sec (linear) or 12,000 rpm (rotary)

- Strong: models with up to 5 Newton force (linear) or more than 3 mN-m (rotary)

- Tiny: as small as 1.8 x 1.8 x 6 mm

- Quiet and smooth

Operating principle

Piezoelectric actuators change shape when electrically excited. A SQUIGGLE motor consists of several piezoelectric ceramic actuators attached to a nut (stator), with a mating screw (shaft) inside.

Applying power to the actuators creates ultrasonic vibrations, causing the nut to vibrate in an orbit – similar to a person’s hips in a “Hula Hoop.” With this unique design, SQUIGGLE motors have:

- No parasitic drag

- Less wasted power

- Zero backlash (with a light pre-load)

- Very high stiffness

- Very high resolution

- Very high force for their size

- Smooth velocity at microscopic speeds

- Off-power hold

- Very small diameter

Linear SQUIGGLE micro motors

In a linear SQUIGGLE motor, the rotating nut turns the threaded screw to create a smooth bi-directional linear motion with sub-micron resolution. Thread friction drives the shaft, directly converting rotary motion to linear motion without the need for a gearbox. The speed and position of the threaded screw can be precisely controlled.

Rotary SQUIGGLE micro motors

In a rotary SQUIGGLE motor, a smooth shaft is in friction contact with the stator. Ultrasonic vibrations of the stator cause the shaft to rotate with milliradian resolution. These direct-drive motors have no need for gear reduction mechanisms.

The design above, with axial preload, is designed for high torque and high resolution. It delivers high peak torque at sustained speeds and is self-locking for high holding torque.

The design above, with orthogonal preload, is designed for speed. It achieves 12,000 rpm, the fastest micro motor on the market.

M3 smart modules, microstages and focus modules

SQUIGGLE motors have excellent position resolution: you can signal the motor to move very small distances, measured in microns or milliradians. However, the motor speed will vary with applied load and device friction. Closed-loop control is recommended for applications requiring exact position, repeatable position, or precise speed.

Our M3 (micro-mechatronic) smart modules deliver this closed-loop control in microstages, focus modules, and other motion systems. We combine our SQUIGGLE motors with precision miniature position sensors to create “ingeniously small” closed-loop actuators and microstages of 12 x 30 mm or smaller. All drive electronics are in the module – you just provide 3.3V and simple, high-level motion commands over a standard serial interface.

Tiny SQUIGGLE micro motor is the basis for New Scale’s M3 smart module design platform.

This animation shows how a linear SQUIGGLE motor vibrates “hula hoop” style and causes the shaft to rotate and translate.